Continuous research investments make PL&TL the ideal partner to entrust the main laboratory analyzes both on raw materials and on finished components.

Analysis on raw materials.

Inside of the laboratory and metrology department, PL&TL performs the following analyzes on raw materials:

It is a thermoanalytical technique in which the difference in the amount of heat required to increase the temperature of a reference sample is measured as a function of temperature. Both the sample and the reference are kept at almost the same temperature during the experiment. Generally, the temperature program for a DSC analysis is designed in such a way that the temperature of the sample holder increases linearly with time. The reference sample should have a well-defined heat capacity in the temperature range to be scanned.

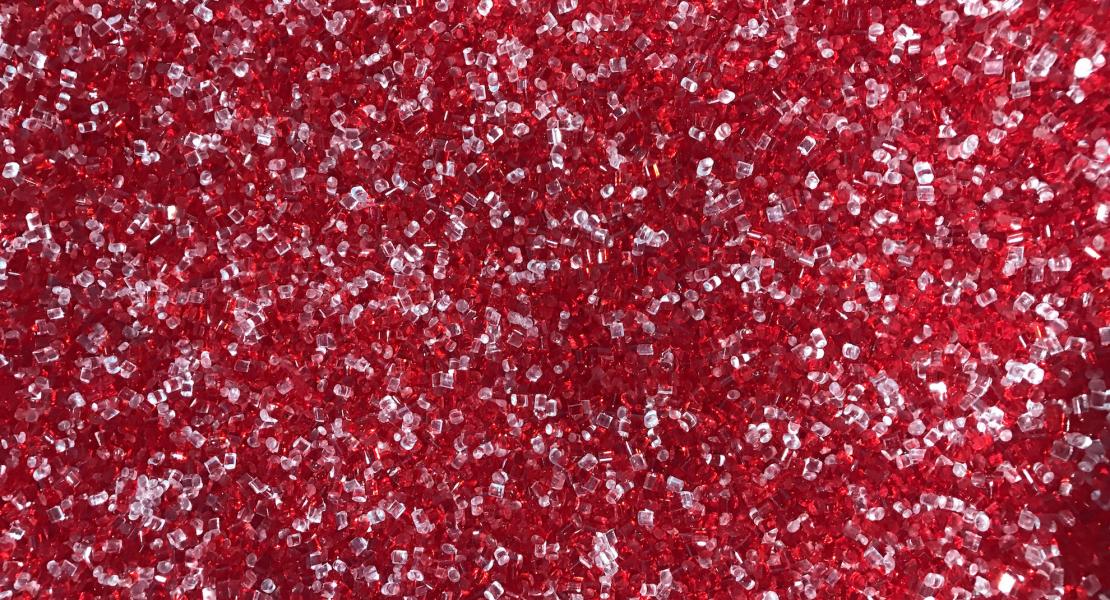

The density is the ratio between the mass of the body (m) and its volume (V), therefore it represents the quantity of matter enclosed in the unit of volume. The polymeric chains are normally disordered, however the lower the content of long branches, the greater the possibility that the macromolecules will have to pack in a reduced space and therefore the greater the density of the polymer. The presence of these more compact and more ordered structures is reflected in many properties of the polymer such as, for example, the optical properties, the melting and softening point, the stiffness and the yield strength.

The Melt Flow Rate is obtained through a measure of viscosity in the molten state, it represents the quantity of polymer, expressed in grams, extruded from a capillary of standard dimensions under a standard weight, in conditions of temperature and time 10 'according to the ISO standard 1133 or ASTM D 1238. The MFR is therefore a characteristic linked to the molecular weight, in the sense that an increase in the molecular weight involves an increase in the viscosity of the polymer and therefore a decrease in the MFR.

The Gloss measures how shiny the surface of a reflective material is, based on a specific angle and its degree of refractive index. A light source is directed on the sample at a specific angle of incidence. A sensor collects the reflected light of the incident beam. A glossy black glass is used as a standard with a refractive index of 1.567 and therefore a gloss equal to 100.

With the help of updated laboratory techniques, PL&TL performs diagnostic analyzes and provides information on the nature and composition of plastic products and artifacts, identifying the polymers, as well as the presence of additives, modifiers, and inorganic fillers. In particular, the analyzes identify the content of ash or residues from calcination by measuring the percentage of charge of thermoplastic materials (eg the percentage of glass fiber).

Analysis of components and finished products.

Inside of the laboratory and metrology department, PL&TL performs the following analyzes on components and finished products:

- 2D metrological survey with drawing peening and relief also from a mathematical model.

- 3D Digital Survey with three-dimensional analysis on chromatic scale of the object, creation of a customized report, customization of analysis tolerances, thickness analysis, measurements on defined sections.

Analysis of components with instrumentation for the measurement of light refracted by catadiopters in compliance with SAE and ECE standards.